Plastic solid movie strains are use for range of merchandise collectively. With films, plastic sheeting, flexible packaging, coating materials, protecting films, and diaper liners. The gadget to make plastic solid movie traces has now not modified notably. In contemporary years and used device offers a excessive return on investment. The regular existence of latest gadget from a correct producer is 20+ years. Its existence can be prolong if well care for and maintained. The most imperative problems when purchasing for new or used equipment are fee, remarkable and transport time.

Plastic solid movie traces is fashion when plastic pellets are fed into a individual extruder, melted, and conveyed. The molten plastic is labour via a die giving the movie its preliminary width and thickness. The plastic exits downwards via the die onto the major roll of a solid unit. It then passes via a sequence of rolls for cooling and thickness manage. The movie is then wou onto a winder. Line charge operation is calculate with the resource of an engineer specifically primarily based on extrusion fee, velocity of the strong unit and velocity of the winder. If these three units are now not calibrat and paired successfully, there can be troubles with the magnificent of the product. When a thicker movie is want, plastic castfilm traces are use in choice to blown movie traces.

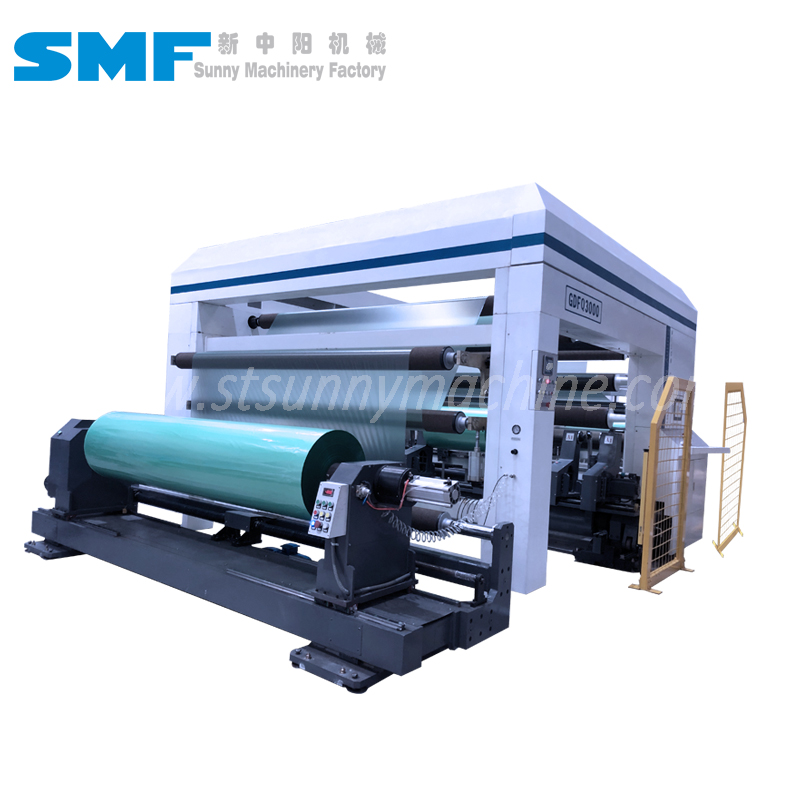

Features of Extrusion Cast Film

Gadget components: When developing strong film, quite a few parts of gadget are require. The first is the extruder. While buying a used extruder, take into account the make, Extrusion Cast Film and horsepower of the motor, barrel venting, sorts of controls, shape of feeder, scenario of the barrel and common look of the used extruder.

The next component is the die: Whilst shopping for used, take into account emblem, version, width and thickness of the slot beginning. Manufacturers consist of Egan, Reifenhauser, Cloeren, EDI, and manufacturing LINES FOR CPP CPE FILM.

The subsequent aspect is the forged unit. Comparable in characteristic to the roll stack from a plastic sheet line, the stable unit controls thickness and cools the forged film. Vital troubles embody face width and diameter of the precept roll and whether or not rolls are water or oil cooled.

Rolls may additionally be hydraulic or pneumatically managed to adjust for sizing. The last factor is a winder. Don’t overlook logo, version, face width and diameter of the rolls, and if it is single or twin turret. Not uncommon producers embody Egan, Welex, Gloucester, Parkinson, and Sano.

A in addition component is a treater that prints on plastic. Bear in thought the width of the rolls, whether or not or no longer single or double-sided, strength rating and logo. Commonplace manufacturers are Wolverine and Gloucester.

When shopping for CPP/CPE cast film line, do no longer forget about the pleasant of the system, age, manufacturer, potential and configurations. The blessings of shopping for used embody on the spot transport and aggressive rate. Pick a desirable manufacturer with protection information.

More info-

Slitter Rewinder, Slitting Machine, Primary Slitter Rewinder